WH-2000T Gas Detector can be used to monitor the gas content in the air, installed in the gas leakage places, with high stability, low power consumption, strong anti-interference characteristics.

| Shell material | Cast aluminum |

|---|---|

| Dimensions | 175mm*138mm*85mm |

| Protection level | IP65, Waterproof and dustproof |

| Measuring Range | 0~100% LEL |

| Operating Temperature | -40°C~70°C |

| Working humidity | 15%~90% RH |

| Detectable gas | CH4, Cl2, ClO2, CO, CO2, H2, H2S, HCl, HCN, NO2, NO, NH3, O2, PH3, SO2, etc. |

WH-2000T Gas Detector can be used in petroleum, petrochemical, metallurgy, environmental protection, gas, fire protection, municipal, city management, chemical, ship, power, process control, sewage treatment, emergency rescue and monitoring.

No reaction to non-flammable gas, only respond to flammable gas;

Fast response, high stability, strong anti -interference;

Not affected by water vapor;

Gas detectors mainly use sensors to detect the concentration of combustible, toxic and harmful gases in the air. There are many types of sensors, including catalytic combustion sensors, electrochemical sensors, infrared sensors, etc. These sensors convert the detected gas concentration into electrical signals, which trigger alarms after processing.

Catalytic combustion sensor: detects the concentration of combustible gas through catalytic combustion reaction, suitable for detecting combustible gases.

Electrochemical sensor:uses electrochemical reaction to detect the concentration of toxic and harmful gases, such as hydrogen sulfide and carbon monoxide.

Infrared sensor: uses the specific infrared absorption characteristics of combustible gas for detection, suitable for detecting gases.

When selecting a combustible, toxic or hazardous gas detector. it is necessary to select appropriate sensor type, detection range, alarm threshold and other parameters according to the specific application scenario and detection requirements.

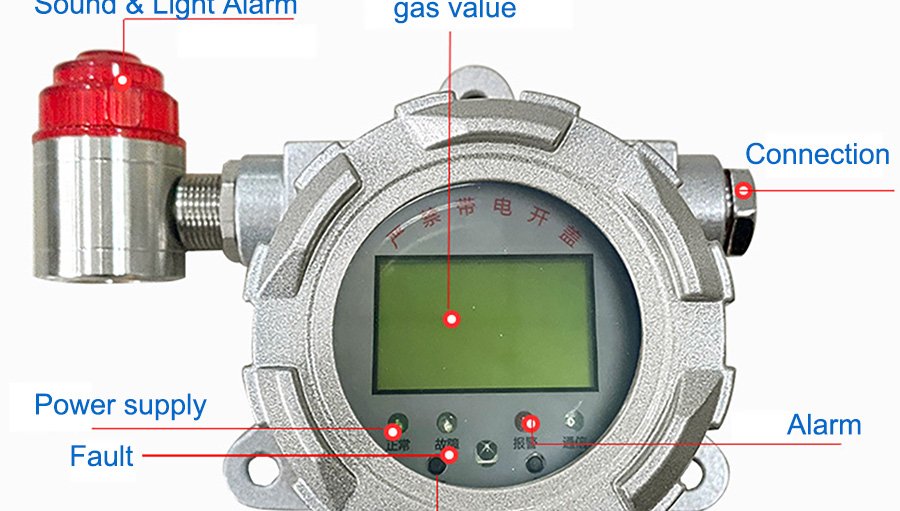

WH-2000T Gas Detector Function:

To ensure the normal operation and accuracy of the alarm, regular maintenance and calibration are required.Daily maintenance includes checking whether the alarm is blocked, whether it is working at rated power, and whether it is installed in a place with high water vapor. The gas detector needs to be regularly inspected and calibrated to ensure its detection accuracy and reliability.