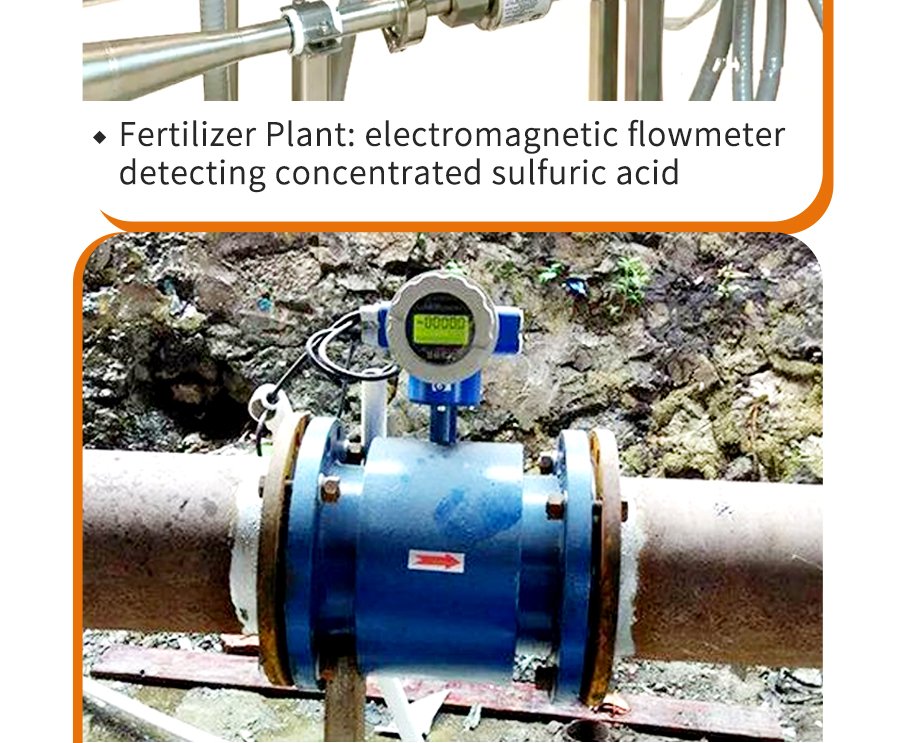

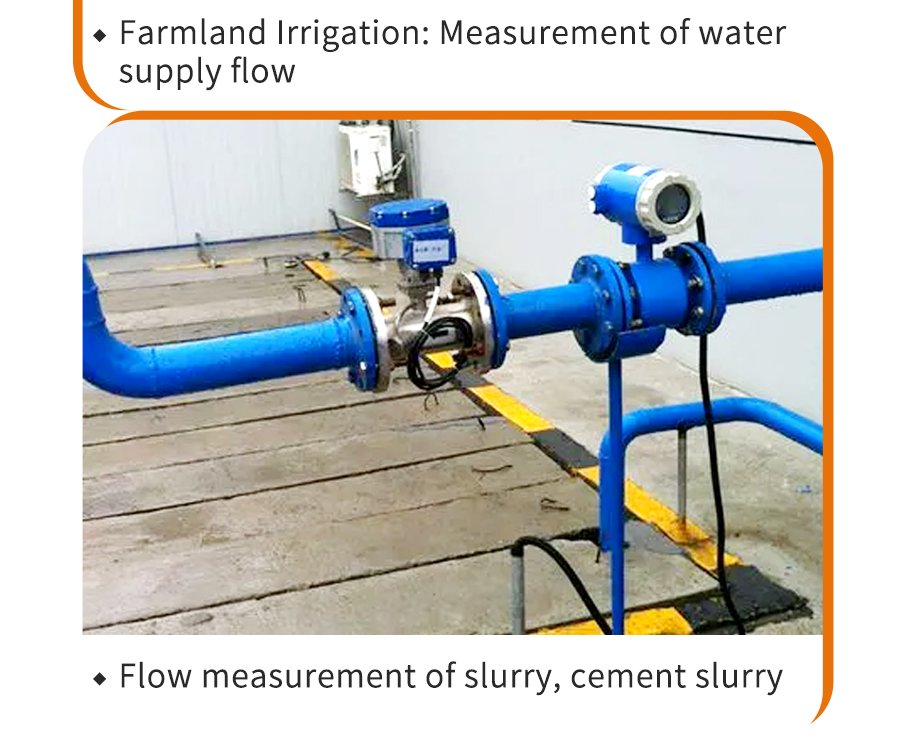

electromagnetic flowmeter are industrial digital flow meters used for measuring the volume flow of conductive fluid in a closed pipe such as water, acids, caustic, and slurries.

Measurement accuracy, not affected by fluid density, viscosity, temperature, pressure and conductivity changes.

| Fluid conductivity | ≥5µS/cm |

|---|---|

| Accurate level | Indicated value: ±0.2%,±0.5% |

| Nominal diameter (mm) | 3-3000 |

| Nominal pressure | 10.0MPa, 6.3MPa, 4.0MPa, 2.5MPa, 1.6MPa, 1.0MPa, 0.6MPa |

| Ambient temperature | -10℃~+60℃/Converter/ Integrated |

| Lining material | Neoprene, PTFE, PU, FEP, PFA, ceramic, etc. |

| Connecting flange material | Carbon steel, stainless steel(304, 316, 316L) |

| Ground ring material | Stainless stee l 1Cr18Ni9Ti |

| Electrical interface | M18*1.5, M20*1.5 |

WHLDE Electromagnetic Flow Meter is industrial digital flow meters used for measuring the volume flow of conductive fluid in a closed pipe

The magnetic flow meter requires a conducting fluid, for example, water that contains ions, and an electrical insulating pipe surface, for example, a rubber-lined steel tube.

Widely used in petroleum, chemical, iron and steel metallurgy, water irrigation, water treatment, process flow measurement and control.

Features:

★ It is not affected by fluid density, viscosity, temperature, pressure and conductivity. The principle of linear measurement can achieve high precision measurement;

★ MODBUS-RS485, Hart, GPRS, Profibus and other communication signal output (optional)

★High definition backlight LCD display, menu operation, simple operation, easy to learn and understand;

★ The internal calculator can display forward cumulative flow, reverse cumulative flow and instantaneous flow, respectively.

★ Due to its direct measurement of fluid velocity, independent of fluid properties, the electromagnetic flow meter offers exceptional accuracy and repeatability over time. This ensures consistent and reliable flow measurements for process control and monitoring purposes.

★ The flow meter is capable of accurately measuring flow in both directions, forward and reverse. This feature is crucial in applications where bidirectional flow is present, such as in chemical processing or water distribution systems, as it allows for comprehensive monitoring and control of fluid movement.

★ The electromagnetic flow meter boasts a wide dynamic range. Accurately measure flow rates over a broad spectrum from very low to very high velocities without the need for multiple sensors or range adjustments. This enhances its versatility across various industrial applications.

★ Having no internal moving parts, it eliminates the risk of wear or clogging. With low maintenance requirements, it is suitable for use in harsh or dirty environments.

★ WHLDE Electromagnetic Flow Meter Remote transmission, remote data monitoring and reading, convenient production and management